Mr. Liu

Leave a message

Mr. Liu

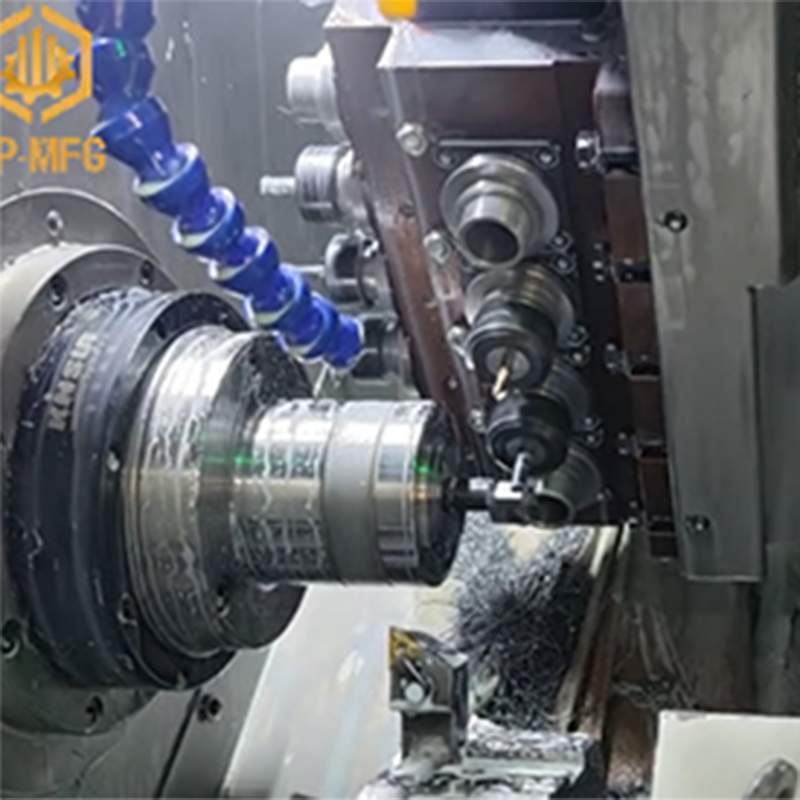

Leave a messageIn sectors with urgent lightweighting demands—such as aerospace and new energy vehicles—aluminum alloys have become critical materials. However, their high-precision CNC Milling processes present significant challenges, often leading to reduced yield rates and uncontrolled costs. Industry experts note this is a systemic engineering endeavor involving materials, processes, and equipment. The core challenges and cutting-edge countermeasures are outlined below:

1. Thermal Deformation Challenge

Manifestation: Significant localized temperature rise during high-speed cutting causes warping in thin-walled, large-surface workpieces.

Strategy: Implement minimum quantity lubrication (MQL) or low-temperature cooling; optimize tool paths by adopting layered symmetrical machining; incorporate thermal compensation algorithms.

2. Residual Stress Release Challenge

Manifestation: Internal stresses redistribute after rough machining, causing springback deformation upon clamping removal.

Strategy: Implement a “rough machining → stress aging → finish machining” process sequence; apply vibration stress aging technology; utilize finite element simulation to predict and optimize machining order.

3. Tool Clogging and Build-Up Edge Challenge

Manifestation: Aluminum chips readily adhere to tools, causing surface roughness and dimensional fluctuations.

Strategy: Select low-friction tools like diamond-coated inserts; employ high-speed, high-feed shear-type cutting; strictly monitor tool life.

4. Insufficient Rigidity in Thin-Wall Structures Challenge

Manifestation: Thin-walled, deep-cavity parts are prone to chatter and tool deflection under cutting forces, compromising accuracy.

Strategy: Employ high-rigidity solid carbide tools with short overhang shanks; utilize adaptive machining systems to maintain constant cutting loads; incorporate removable process ribs for temporary support.

5. Hole Machining Accuracy Control Challenges

Manifestation: Drilling frequently produces flared holes and axis deviation, particularly during inclined surface machining.

Strategy: Strictly implement center drill positioning and staged boring processes; use specialized deep-hole drills with high-pressure internal cooling; achieve normal-angle entry on 5-axis machines to ensure perpendicularity.

6. Multi-Process Coordination Challenge

Manifestation: Multi-process collaboration involving Laser Cutting, bending, welding, and CNC machining often leads to assembly difficulties due to tolerance accumulation.

Strategy: Implement integrated metal manufacturing services consolidating all processes on a single platform; establish a unified reference system; Apply digital twin technology for full-process deformation simulation and tolerance optimization.

Summary

Addressing these systemic challenges requires transcending single-process thinking and adopting collaborative innovation in process design and flow control. Integrating CNC milling services with advanced manufacturing technologies while implementing the above targeted strategies represents the essential pathway to achieving high precision, stability, and efficiency gains in aluminum component machining.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.